Automatic Selective Door Operation

SIL 2 Pre-Certified | Compatible with Any TCMS | Balise-Free Positioning

EKE-Electronics’ ASDO is a SIL 2 pre-certified system designed as a generic solution that integrates easily with any Train Control and Management System (TCMS). The system operates balise-free using odometry and GNSS as standard and includes Correct Side Door Enabling (CSDE) for enhanced safety.

ASDO enables operators to deploy longer trains on routes with short platforms without infrastructure modifications, supporting both new builds and refurbishment projects.

EKE-Electronics’ ASDO is in service worldwide; tested and proven in real-world operations. Optional features include advanced positioning technologies such as RFID beacons and ETCS Eurobalises for networks requiring additional precision or redundancy.

What is ASDO?

Automatic Selective Door Operation (ASDO) is a railway safety system that ensures only doors adjacent to a platform are released for passenger use, preventing unsafe disembarkation and improving operational efficiency.

Unlike traditional systems that operate doors by coach or car, ASDO controls doors individually, providing precise alignment with platform edges for enhanced passenger safety.

ASDO is widely used in modern rail networks to manage short platforms and complex station layouts.

What Makes EKE-Electronics' ASDO Different?

EKE-Electronics’ ASDO solution combines engineering excellence with flexibility, offering unique advantages:

- Pre-certified SIL 2: Reduce approval time and integration risk, ensuring faster deployment and lower costs.

- Easy TCMS Integration: Easily integrates with any Train Control and Management System (TCMS).

- Balise-Free as Standard: Uses odometry and GNSS for precise train positioning—no costly trackside hardware required.

- Faster Deployment: A standardised architecture minimises engineering lead time and reduces lifecycle costs without compromising safety or reliability.

- Integrated Correct Side Door Enabling (CSDE): Adds an extra layer of safety by ensuring doors open only on the platform side.

- Modular Design: Scalable for future upgrades and additional safety features.

- Retrofit & New Build Compatibility: Ideal for modern fleets and refurbishment projects.

- Compatible with Various Train Configurations: Supports EMU/DMU units, locomotives, passenger cars, and mixed formations.

- Expandable Functionality: Additional features such as Hot Axle Box Detection (HABD) can be integrated into the same system, reducing hardware footprint and simplifying maintenance.

- Proven Worldwide: EKE-Electronics’ ASDO is deployed across global rail networks. Tested, trusted, and proven to deliver reliable performance in real-world operations.

Why ASDO Matters

- Enabling Longer Trains on Short Platforms: Safely deploy longer trains on routes with short platforms, increasing capacity and revenue without requiring infrastructure changes.

- Safety at Short Platforms: Prevents passengers from stepping onto unsafe areas.

- Correct Side Door Enabling (CSDE): Activates doors only on the platform side.

- Reducing Human Error: Automates door selection logic for consistent safety.

- Operational Efficiency: Eliminates manual door selection errors.

- Improved Passenger Experience: Reduces inconvenience caused by closed platform-aligned doors, requiring passengers to board or exit through other trainsets.

Core Features

ASDO includes essential safety and operational features designed to ensure reliable performance across diverse rail environments.

SIL 2 Pre-Certified

Pre-certification minimises engineering effort, accelerates deployment, and cuts lifecycle costs.

Integrates easily with any TCMS, reducing integration effort.

Door and step status is maintained when the train changes direction or during cab switches.

Correct Side Door Enabling (CSDE)

CSDE functionality is included in ASDO, enabling only the doors on the correct side while disabling those on the wrong side. ASDO gives individual control over each door via digital output.

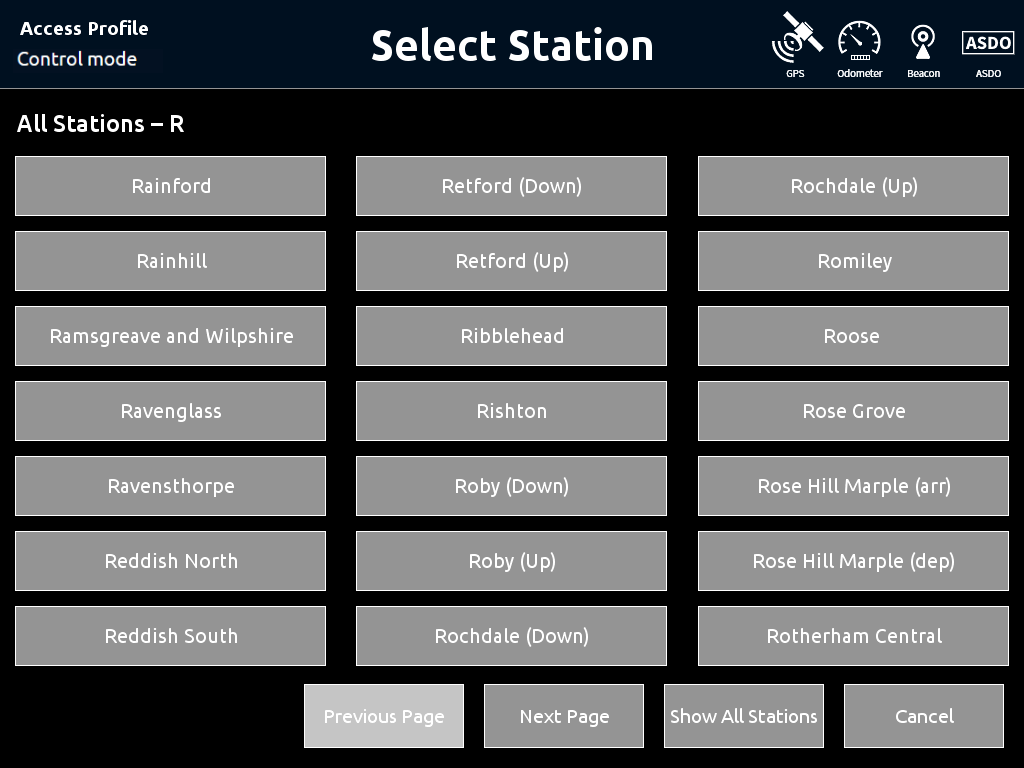

The ASDO Station Database stores station and platform data for building the network. It’s easy to update for route or track changes and includes version control, viewable via the ASDO HMI.

The system automatically detects and manages train configuration, including the number of cars and their sequence, to ensure accurate door control and platform alignment.

Accurate Identification Of Train’s Location

Our solution integrates GNSS satellite input with odometry-based speed and distance data for precise dead reckoning, ensuring accurate train location and seamless platform alignment.

The system interfaces with the Passenger Information System (PIS) to provide accurate real-time platform and train location data for passenger displays.

The system provides diagnostic data to the Train Control and Management System (TCMS), including sensor status, fault codes, and operational health metrics for proactive maintenance.

Intuitive SIL 2 Compliant ASDO User Interface

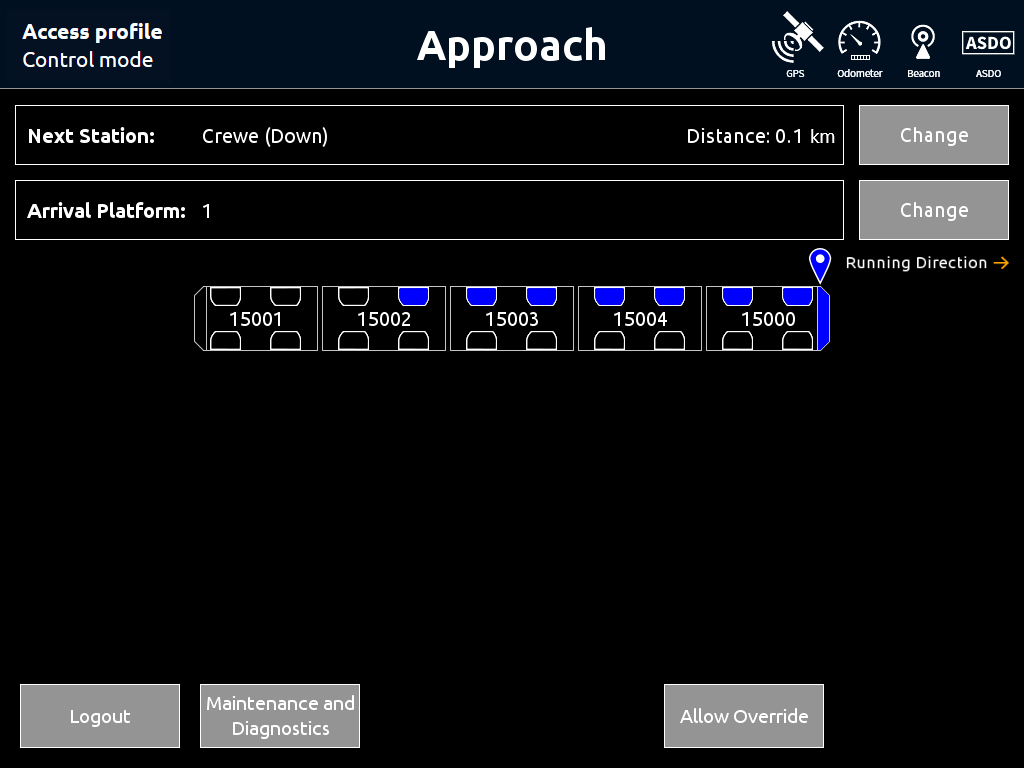

The ASDO Human-Machine Interface (HMI) provides clear, essential door and station information to the crew, ensuring efficient operations and informed decision-making. Designed for usability and compliance, the HMI meets SIL 2 requirements and follows ISO 9241 and EN 16186-3 standards.

As the train approaches a station, the display shows the next stop and the assigned arrival platform. If a change is needed, the crew can update this information using the change button.

The system cross-references the train’s determined location with the ASDO Station Database. Safe-to-open doors are highlighted in blue on the screen, while a map pin clearly marks the front of the train. If necessary, the crew can override the door configuration from this interface.

For maintenance and diagnostics, dedicated screens allow technicians in the depot to configure wheel diameter, monitor ASDO status, verify software versions, and perform troubleshooting.

In addition to the EKE HMI, the ASDO system can also interface with non-EKE display units for drivers, guards, or maintenance, either shared with other train functions or dedicated to ASDO. Communication uses IP over Ethernet with the SDTv2 safe protocol and TRDP, ensuring SIL 2 compliance.

How does ASDO work?

The Automatic Selective Door Operation system begins by verifying the platform configuration to ensure that doors open only at the correct locations. It uses odometry, in conjunction with GNSS and data from the ASDO Station Database, to locate the train and identify the station. This information determines the number of doors to open and on which side(s) of the train. If necessary, balises or beacons can also be utilised.

Build ASDO using the following modules

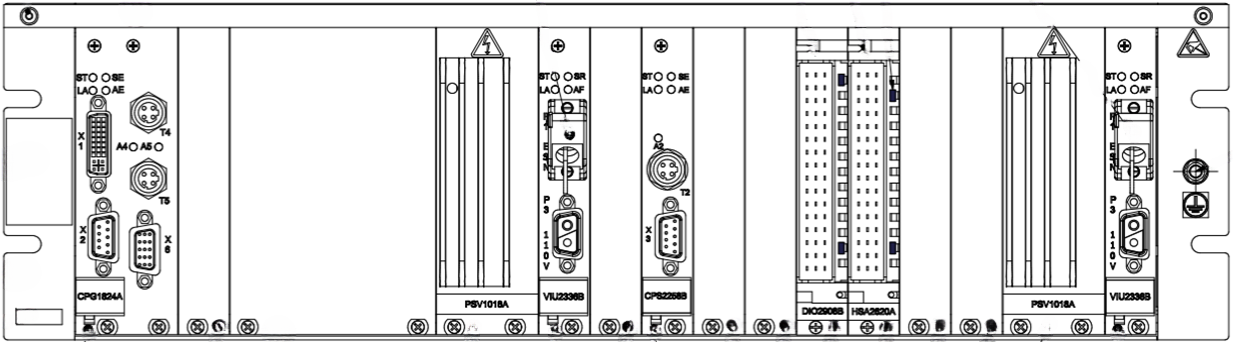

The ASDO system usually consists of two Central Processing Units (CPU), I/O modules, power supplies and a rack. Click on an image to explore related content.

Modular Concept

Below is an example of an ASDO system made up of a selection of common modules. The modules are the minimum required for ASDO, with additional modules available for expanded functionality. For example, HABD is often integrated within the same system. Hover over each area to view a brief description or click to access the full module page.

CPU with Graphical Display Controller (CPG)

Supports DVI and Ethernet display interfaces

Power Supply Unit for VME (PSV)

Provides power for the ASDO HMI

Vehicle Identification Unit (VIU)

Required for door identification for the HMI.

CPU with Serial Links (CPS)

A central processing unit providing serial communication interfaces.

Digital Input Output Module (DIO)

A Digital Input Output Module for delivering digital ASDO signals to the ASDO CPU modules.

High Speed Analogue Input Module (HSA)

Converts analogue signals and makes them available to the ASDO CPU modules.

Power Supply Unit for VME (PSV)

A second power supply unit required to power the ASDO system

Vehicle Identification Unit (VIU)

A second VIU required for door identification for the ASDO System

Application Software

The ASDO application software is built on an open-source Linux platform and is coded in C and C++.

Unlike our TCMS platform, which allows users to code their own applications, ASDO application software is built by EKE-Electronics. This protects the SIL 2 certification which requires tools. processes and knowledge about how to produce SIL Safety applications.

ASDO Configurations

EKE-Electronics’ ASDO system offers a range of optional features to enhance safety, positioning accuracy, and integration flexibility. All options comply with SIL 2 safety standards and are designed for seamless integration with TCMS.

Purpose: Provides platform identification and positioning data using RFID technology.

- RFID beacons installed before platforms deliver data on platform ID, length, side, and train direction.

- ASDO validates beacon data against the Station Database and ESN configuration.

- SIL 2 certified data source for enhanced safety.

- Flexible installation: one or two readers per train unit, positioned at cab ends or mid-unit.

- No additional ASDO hardware required for later integration.

Purpose: Enables ASDO to use ETCS Packet 44 data for platform identification.

- Balises installed before platforms provide platform ID, length, and train direction.

- ASDO prioritises ETCS Packet 44 data over RFID beacon data.

- SIL 2 compliance when using TRDP and SDTv2 protocols.

- No extra ASDO hardware needed for future ETCS integration.

Purpose: Determines the exact train position for safe door operation.

- Combines RFID beacon data with platform dimensions stored in ASDO database.

- Accuracy: ±1.0 m depending on speed and beacon placement.

- Enables CSDE for correct side door opening.

Purpose: Ensures safe communication between ASDO and train systems.

- TRDP and SDTv2 protocols are available on the EKE platform with the required interfaces.

Purpose: Configures sliding step patterns for each station.

- Displays step patterns on ASDO HMI alongside door patterns.

- Sends enabling signals to TCMS for step control (not a safety function).

Purpose: Allows trains to align doors at multiple platform points.

- Configurable in Station Database for different train compositions.

- Supports PRM (persons with reduced mobility) door alignment and flexible stopping strategies.

Why Choose EKE-Electronics for your ASDO?

EKE-Electronics combines decades of rail expertise with proven ASDO technology, delivering reliable, safety-certified solutions for operators worldwide. Our systems are designed for flexibility, fast deployment, and future upgrades, ensuring long-term value across diverse rail networks.

With over 2,000 ASDO installations worldwide, EKE-Electronics offers a proven solution trusted by rail operators for safety, reliability, and flexibility. Our global experience ensures consistent performance for new builds, refurbishments, and mixed fleet configurations.

With extensive experience and processes aligned to EN 50126, EN 50129, and EN 50716 standards, we deliver safety applications that are rigorously developed and tested. Operators can rely on a solution that prioritises safety without compromising performance.

EKE-Electronics’ ASDO uses a modular, future-ready architecture for fast deployment and easy upgrades—whether adding ETCS Eurobalises or RFID beacons as they become available. This ensures operators can adapt without costly system replacements.

Frequently Asked Questions

What does ASDO stand for?

ASDO stands for Automatic Selective Door Operation.

It is a train door control system that automatically controls train doors at each station stop by checking train location and platform configuration to ensure only safe doors open, improving passenger safety and comfort

What is Automatic Selective Door Operation (ASDO)?

Automatic Selective Door Operation (ASDO) is a train door control system that automatically controls train doors at each station stop by checking train location and platform configuration to ensure only safe doors open, improving passenger safety and comfort.

How does ASDO work?

The Automatic Selective Door Operation system begins by verifying the platform configuration to ensure that doors open only at the correct locations. It uses odometry, in conjunction with GNSS and data from the ASDO Station Database, to locate the train and identify the station. This information determines the number of doors to open and on which side(s) of the train. If necessary, balises or beacons can also be utilised.

What is an ASDO Station Database?

The ASDO Station Database contains essential infrastructure details like stations and platforms. This database builds the “station network” for Automatic Selective Door Operation usage and can be easily updated by operators to reflect changes such as track renewals, new routes, or stopping patterns.

What is Selective Door Operation (SDO)?

Selective Door Operation allows the crew to manually select the doors that can be safely opened.

What is Corrective Side Door Enabling (CSDE)?

Correct Side Door Enabling is a train door control system that ensures that train doors open on the correct side of the train at each station platform. This is important for passenger safety and comfort, as passengers need to be able to easily access the train without having to cross over the tracks.

What positioning solutions are available for ASDO?

We offer multiple Automatic Selective Door Operation options to address diverse needs.

- Odometry with GNSS,

- Balises/beacons and

- Odometry.

This flexibility allows us to adapt to various operational scenarios, recognising our customers’ unique preferences and constraints.

What is SIL?

SIL or Safety Integrity Levels are defined levels of risk reduction applied to safety-related systems. They are designed to automatically prevent dangerous failures or to control them when they occur. SIL levels range from SIL 1 to SIL 4, with SIL 4 providing the highest level of risk reduction.

For more information, read our blog about implementing SIL for train products.

What are Safety Integrity Levels?

Safety Integrity Level (SIL) is a measure of the reliability and risk reduction capability of safety-related systems. For railway applications, SIL levels are defined by standards such as IEC 61508 and EN 50126/EN 50128/EN 50129.

What is Packet 44?

Packet 44 or P44 is a data packet used within the ETCS framework to convey information related to the position of trains. The primary purpose of P44 is to ensure that trains receive timely and precise location data, which is essential for maintaining safe distances between trains and thus preventing collisions.