LAM: Lateral Acceleration Monitoring

Lateral Acceleration Monitoring is a SIL 2 on-board monitoring system that detects abnormal lateral movements in real-time, thereby enhancing passenger comfort, reducing injury risks, and functioning as a predictive maintenance tool.

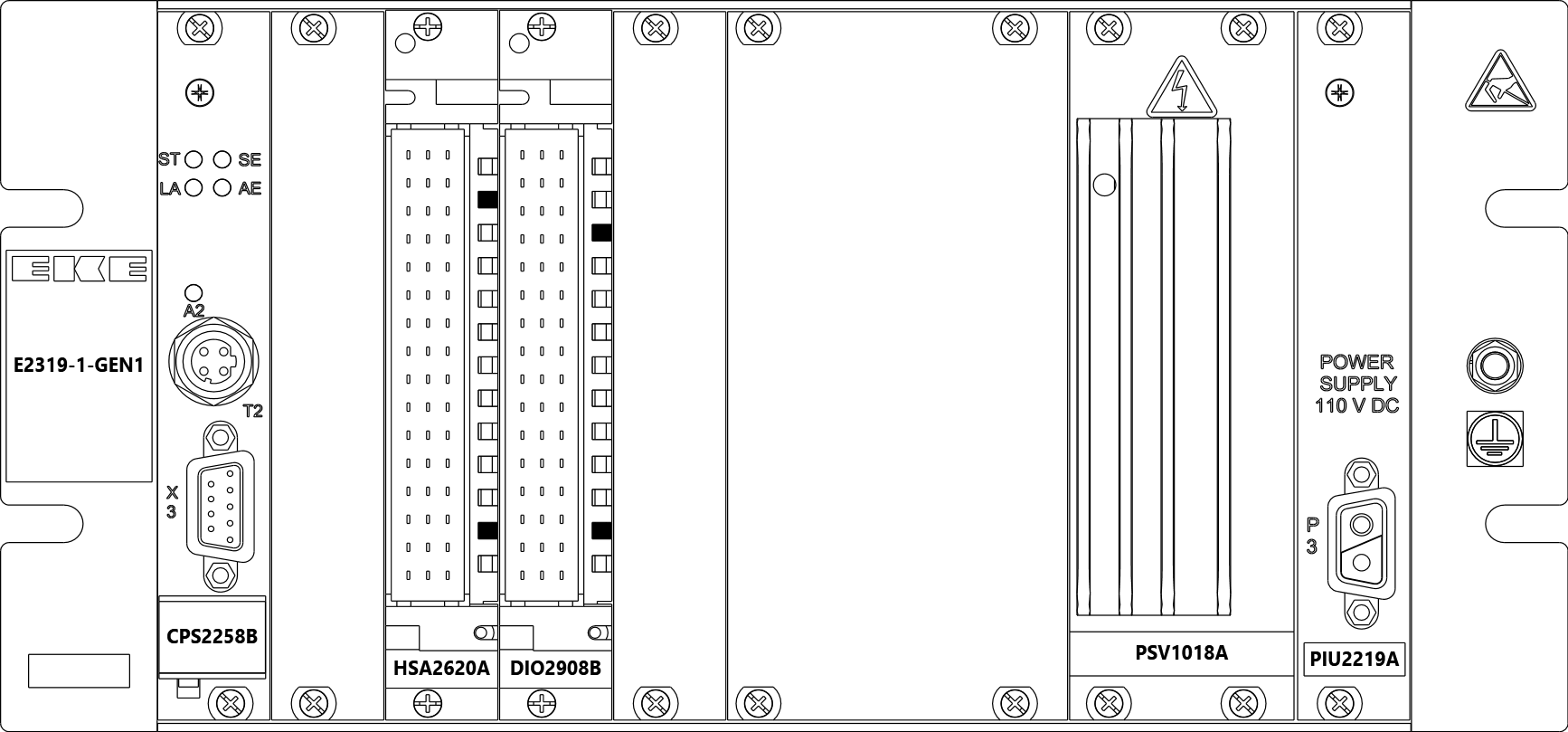

Build a Lateral Acceleration Monitoring System using the following modules

Click on an image to explore related content.

Modular Concept

Below is an example of an LAM system made up of a selection of common modules. The modules are the minimum required for LAM, with additional modules available for expanded functionality. For example, HABD is often integrated within the same system. Hover over each area to view a brief description or click to access the full module page.

CPU with Serial Links (CPS)

A central processing unit providing serial communication interfaces.

High Speed Analogue Input Module

Provides a standard interface for analogue input signals.

Digital Input Output Module (DIO)

Receives digital signals through its input channels and delivers them to the train computer’s Central Processing Unit (CPU) module for processing.

Choose the appropriate input output module to capture the signals you need.

Power Supply Unit for VME (PSV)

Provides power for the system.

Power Input Unit (PIU)

Used to pass train battery voltage to the EKE-Trainnet® Power Supply Unit for VME (PSV) module

Application Software

The Lateral Acceleration Monitoring application software is built on an open-source Linux platform and is coded in C and C++.

Unlike our TCMS platform, which allows users to code their own applications, the Lateral Acceleration Monitoring application software is built by EKE-Electronics. This protects the SIL 2 certification, which requires tools, processes and knowledge about how to produce SIL Safety applications.

How does Lateral Acceleration Monitoring work?

Vibrations can have multiple sources, including engines, suspensions, wheelsets, tracks, etc. Accelerometer sensors can be placed in the bogie or on the car body. As the train travels, the vibrations measured by these sensors are processed. Should these vibration measurements trigger the threshold values, an alarm is set.

- Measure: Accelerometers are placed in the axle box or on the car body.

- Convert: The vibration measurements are converted into lateral acceleration values, providing quantifiable data on the train’s lateral movement.

- Assess: The lateral movements are assessed to determine if they have exceeded the criteria for acceptable lateral accelerations.

- Alarm set: An alarm is set to either notify maintenance teams about abnormalities or even automatically stop the train in case of immediate danger.

Lateral Acceleration Monitoring Capabilities

Lateral Acceleration Monitoring has several core capabilities that empower proactive maintenance strategies. Leveraging real-time data processing and configurable alarm levels, the system provides timely insights into asset health, enabling predictive interventions before potential failures occur.

The LAM system captures and processes data in real-time, following industry-standard methods like those in UIC 518:2009. This capability enables swift analysis of lateral acceleration values, empowering operators to promptly make informed decisions. By monitoring and analysing vibrations continuously, operators can address safety concerns and optimise operations in real-time, ensuring seamless operations and enhancing safety, efficiency, and reliability across their rail networks.

Operators have the flexibility to configure multiple levels of alarms, customising them to suit specific safety thresholds or operational preferences. Criteria for acceptable lateral accelerations are defined by setting up threshold values, which can be obtained from standards or by performing online testing.

Several levels of alarms can be set, either to notify maintenance teams about abnormalities or even to automatically stop the train in case of immediate danger. In most cases, abnormalities can be detected before the issue represents a safety risk.

The system’s customisable alarm settings ensure that operators receive timely alerts tailored to their unique requirements, enabling the Lateral Acceleration Monitoring system to be used as a predictive maintenance tool, allowing for better maintenance planning. This empowers operators to proactively address potential safety risks.

Redundancy can be built into the Lateral Acceleration Monitoring system, further enhancing its reliability. Redundancy ensures that even in the event of a sensor failure or system malfunction, there are backup mechanisms in place to continue monitoring lateral vibrations effectively. Redundancy minimises the risk of missed detections and ensures continuous monitoring, contributing to the overall safety and reliability of rail operations.

Why Choose EKE-Electronics for your Lateral Acceleration Monitoring?

Our TCMS supports SIL 2 development, with some key modules already pre-certified. Its modular design allows you to select only the features you need, creating a cost efficient, flexible and versatile solution with a simplified architecture.

Drawing on our expertise in safety-critical functions and compliance, our LAM system stands as a trusted choice for the rail industry. Adhering to safety integrity levels (SIL) and industry standards like EN 50126/50128/50129, we assure customers of our product’s reliability and robustness. This underscores our commitment to technical excellence and regulatory compliance, giving you a competitive edge in the market.

At the core of our LAM system is a profound understanding of your unique needs and priorities. With our modular approach, we build solutions to directly tackle your specific pain points and challenges. This ensures that you can consistently deliver exceptional service to your customers, cultivating trust and loyalty in your brand. Our system is not just about monitoring—it’s about empowering you to excel in every aspect of your operations.

maintenance

By detecting abnormalities before they become safety risks, our system ensures uninterrupted service and passenger comfort. Moreover, with its capability to provide valuable insights into wheelset conditions and track damages, you gain the advantage of enhanced maintenance planning.